Schaeffler and SD Guthrie International sign MOU to enhance mechanization and digitalization solutions and services for advanced control & predictive maintenance

2024-10-09 | Singapore

- Schaeffler and SD Guthrie sign memorandum of understanding in the field of advanced control and predictive maintenance

- Memorandum of understanding focuses on introducing advanced control and predictive maintenance solutions to support SD Guthrie’s digital transformation agenda

Schaeffler, the motion technology company, and SD Guthrie International have signed a memorandum of understanding (MOU) to explore the use of advanced control and predictive maintenance solutions to support production reliability and machinery operations.

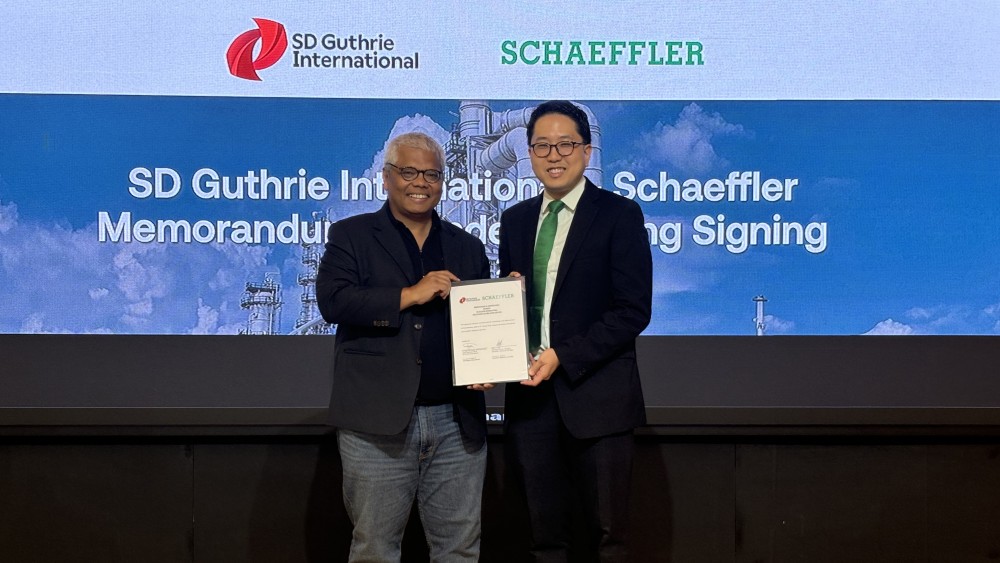

The signing ceremony was attended by Kelvin Chong, Managing Director, Malaysia, and Dr Shariman Alwani, Chief Executive Officer, SD Guthrie International. The memorandum of understanding will see Schaeffler leveraging its technical expertise, industrial knowledge, and Lifetime Solutions portfolio to support SD Guthrie International’s global digital transformation agenda for its plant operations.

“In this decade of efficiency, industry operations have taken a transformative shift toward digitized solutions to minimize disruptions through smarter operations,” says Kelvin Chong. “By bringing together our ever-growing store of digital expertise and industry know-how, our goal is to support SD Guthrie International in maximizing their operation productivity with cost-effective solutions.”

Eliminating Downtime with the OPTIME Ecosystem

The OPTIME Ecosystem is designed to minimize downtime in manufacturing operations through various integrated components. At the heart of this system is the OPTIME Digital Service, which includes an intuitive mobile app, a dashboard, and an export viewer, allowing users access to essential information and a comprehensive overview of all machines and lubrication points anytime and anywhere.

This is made possible through the OPTIME Cloud, which boasts unlimited processing power and capacity, allowing vast amounts of data to be processed and analyzed. The data is sourced directly from various OPTIME vibration sensors and intelligent lubricators that are transmitted securely to the OPTIME gateway – a stand-alone device that supports secure cloud connectivity and IT infrastructure integration.

A pivotal element of the OPTIME ecosystem is its automatic and self-healing OPTIME mesh network that connects the various OPTIME devices. The easy-to-set-up mesh network allows machines to be remotely monitored. Additionally, machine lubrication is now simplified with OPTIME C1, the world’s first smart lubricator, which helps maintenance managers monitor the filling levels of each lubricator and any potential lubrication problems.

Alfred Lee, President Bearings & Industrial Solutions Asia/Pacific, said, “As smart products and the networking of components come increasingly to the forefront of industrial transformation, we aim to leverage the potential of digitalisation to provide added value to our customers and partners. It is here where our OPTIME Ecosystem, part of our Lifetime Solutions portfolio, provides decisive value in terms of operational efficiency and cost-effectiveness for industrial transformation.”

The agreement follows a project collaboration with SD Guthrie International to provide predictive maintenance solutions at its plant in Port Klang, Malaysia, to detect emerging damage to machinery at an early stage. The implementation of Schaeffler’s condition monitoring and intelligent lubrication solutions saw minimized unplanned downtime in 5 months, leading to more than 50,000 euros in savings.

To learn more about the OPTIME Ecosystem and how it can transform manufacturing operations, please visit https://medias.schaeffler.my/en/monitor/optime-ecosystem

Publisher: Schaeffler (Singapore) Pte. Ltd.

Country: Singapore

Press releases

Package (Press release + media)