Schaeffler announce launch of Asia Pacific Remote Monitoring Center to provide value-added expert services to customers in the region

2025-10-06 | Singapore

- Staffed by expert vibration analysts, the new Remote Monitoring Center enables Schaeffler to deliver its OPTIME Expert Services, providing hands-on guidance for predictive maintenance across Asia Pacific.

- Already monitoring over 8,000 sensors for 77 customers and 14 service partners, driving reductions in unplanned downtime and improving operational resilience.

- The center expands Schaeffler’s worldwide footprint in industrial asset monitoring, reinforcing the company’s commitment to customer-centered innovation and operational excellence.

Schaeffler, the motion technology company, has officially announced the commencement of its Schaeffler Industrial Lifetime Solutions Remote Monitoring Center (RMC) Asia Pacific as part of its strategic move to enhance the reliability of industries across the region.

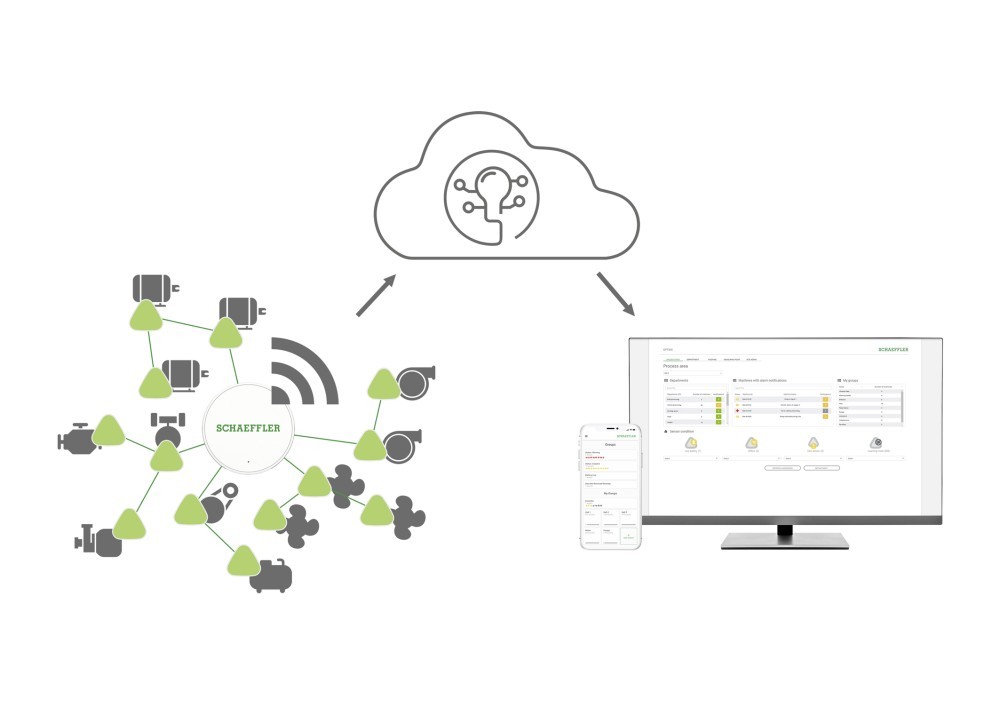

Staffed by a team of expert vibration analysts, the RMC delivers comprehensive support to industrial customers and service partners in India, South East Asia, and the wider Asia Pacific region. The center leverages state-of-the-art AI and machine learning technologies to monitor equipment, predict potential faults, and help companies reduce operating costs and resource strain.

“With the launch of the Remote Monitoring Centre, I am confident that we can better support our customers in the region with predictive maintenance strategies to optimize their plant operations by reducing the unplanned downtime, ensuring business continuity,” says Alfred Lee, President, Bearings and Industrial Solutions, Asia Pacific.

Industrial organizations across the region continue to face challenges such as improper sensor mounting, inaccurate data collection, limited expertise, missed early warning signs, and escalating repair costs. These issues often divert internal teams from core business functions and threaten operational efficiency.

To address these issues, the new remote monitoring center enables Schaeffler to offer its Expert Services, a comprehensive support model that provides hands-on guidance from implementation to long-term optimization through a structured “Closing the Loop” three-phase approach, ensuring customers benefit from the monetary and production upsides.

Since starting its operations in Asia Pacific on 1 August, the Remote Monitoring Center has supported more than 8,000 active sensors, monitoring industrial assets for over 77 customer organizations, alongside 14 certified service partners.

The new Remote Monitoring Center further complements similar centers established in Schaeffler’s operations in Germany, China and Australia.

“Our mission is to make advanced monitoring solutions accessible to all Schaeffler customers worldwide, turning zero unplanned downtime into a tangible reality. As we expand, our goal is to empower our customers’ maintenance teams with expert insights, reduce operational costs, and free up internal resources to focus on other aspects in operating their plant more efficiently,” Alfred added.

Publisher: Schaeffler (Singapore) Pte. Ltd.

Country: Singapore

Press releases

Package (Press release + media)